* Please refer to the English Version as our Official Version.

* Please refer to the English Version as our Official Version.

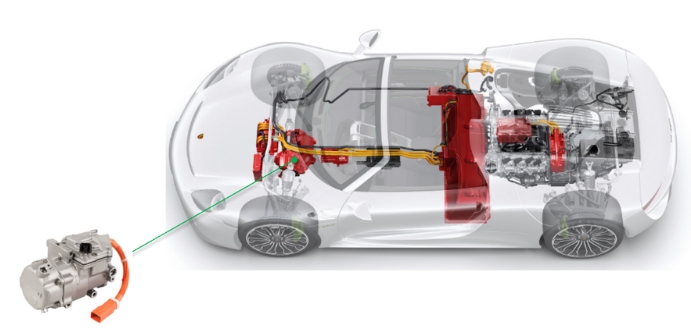

The compressor is a part of the car air conditioning system. It compresses the refrigerant into a high-temperature and high-pressure gas, which then flows through the condenser, throttle valve, and evaporator for heat exchange, achieving cold and hot exchange inside and outside the car. Traditional fuel vehicles are powered by the engine and rotate the compressor through a belt. New energy vehicles, on the other hand, detach from the engine and use batteries as power to drive brushless DC motors through inverter circuits, thereby driving the compressor to rotate and achieving the cold and hot exchange function of air conditioning.

The electric compressor is the core component of thermal management for electric vehicles. In addition to improving the environmental comfort inside the cabin (cooling, heating), it plays an important role in temperature control of the electric drive system, which is crucial for the battery's service life, charging speed, and range.

Electric compressors need to meet the increasing demand, including low cost, smaller size, less vibration and noise, higher power levels, and higher energy efficiency. These requirements cannot be separated from the design of compressor drive circuits and the selection of excellent components.

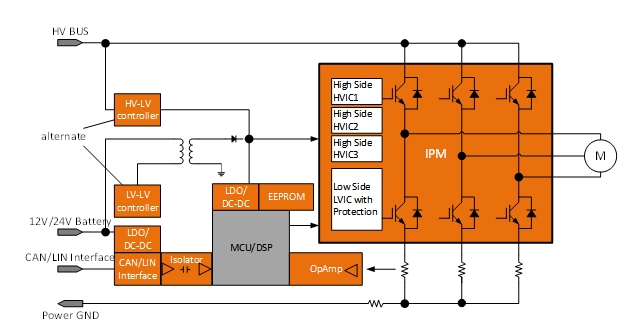

The functions of the electric compressor controller include: driving the motor (inverter circuit: including ASPM module or discrete devices equipped with gate drive, voltage/current/temperature detection and protection, power conversion), communication with the host (CAN or LIN, receiving start stop and speed signals, sending operation status and fault signals), etc. Ansemi has corresponding solutions in each circuit (Figure 1). This article focuses on exploring the ASPM module scheme for inverter circuits.

ASPM Automotive grade Intelligent Power Module

Automotive Smart Power Module (ASPM) is a modular solution that integrates power semiconductor devices, driver circuits, and control circuits, aiming to provide efficient, reliable, and compact power conversion and control.

The advantages of ASPM automotive grade intelligent power module

The ASPM module power chip and IC chip are directly soldered onto a copper pin frame, then covered with ceramics on the pin frame, and finally cast into shape in epoxy resin. Compared to the discrete scheme, it greatly reduces parasitic inductance, reduces the number of devices in the overall design, and the required area of the PCB board, providing high insulation and voltage resistance while maintaining good heat dissipation performance.

1. Cost

If the cost of ASPM modules and discrete devices is compared separately, the cost of the modules will be higher. However, in terms of overall system cost, considering PCB, mechanical installation, quality, and performance costs, the higher the system power, the more advantageous the use of ASPM modules will be.

2. Thermal performance

In the design of electric compressors, heat dissipation characteristics are a key factor that directly affects the current carrying capacity of the module. Therefore, the heat dissipation characteristics of packaging are crucial in determining its performance. There is a trade-off between heat dissipation characteristics, packaging size, and isolation characteristics. The key to excellent packaging technology lies in optimizing packaging dimensions while maintaining excellent heat dissipation performance without sacrificing isolation levels.

Taking the 650V ASPM27 series as an example, these modules adopt DBC (Copper Clad Laminate) substrate technology, which brings good heat dissipation performance. The power chip is directly mounted on the DBC substrate, allowing heat to be more effectively transmitted from the chip to the outside, thereby improving heat dissipation efficiency and reliability. This is crucial for maintaining the long-term stability of the power module under high current operation and extending its service life.

Because temperature directly affects the performance, reliability, and lifespan of products, most designers hope to have a precise understanding of the temperature of power chips. However, due to the fact that the power chips inside the package (such as IGBT and FRD) operate under high voltage conditions, it becomes difficult to directly measure their temperature. In the past, due to cost and technical reasons, designers often did not directly measure the temperature of power chips, but instead used external NTC thermistors to detect the temperature of modules or heat sinks. Although this method is simple, it cannot accurately reflect the temperature situation of the power components themselves. In the 1200V ASPM34 series, a major innovation in design is the integration of NTC thermistors and power chips on the same ceramic substrate, enabling temperature sampling within the module. In this way, the actual temperature condition of the power chip can be more accurately reflected, allowing developers to have a clear understanding of the internal temperature margin of the module, and taking corresponding measures in system control. For example, at low speeds, poor system heat dissipation can cause the module temperature to be too high, and the frequency can be appropriately increased to strengthen heat dissipation; Alternatively, reduce the frequency appropriately or provide over temperature shutdown protection during high frequency and high power operations. The ASPM module of Ansemy is designed with a switching frequency of over 20kHz (ASPM27-V3 can reach 40kHz, FS4's IGBT switching speed is faster, and switching loss is lower), which can easily meet the sampling requirements of existing electric compressors with speeds below 15000 rpm.

3. Power density

Compared to the discrete IGBT scheme, ASPM greatly reduces the line inductance without considering the electrical safety distance between discrete devices; The insulation between the pins and the heat dissipation surface can reach up to 2500V, without the need for additional insulation gaskets like IGBT. And it is easy to install and has high reliability.

4. Reliability

The ASPM module integrates optimized protection circuits and drivers that match the characteristics of IGBT switches, which can greatly shorten circuit matching and development time for developers. By integrating undervoltage protection and short circuit protection functions, the reliability of the system has been greatly improved. The built-in high-speed HVIC has the ability to resist dv/dt and negative pressure, providing an IGBT driving capability that does not require optocoupler isolation. The integrated HVIC allows for the use of a single power drive topology that does not require a negative power source.

To achieve higher reliability, the mismatch of CTE between different materials can be minimized as much as possible. Ansemy's ASPM module is certified by AEC-Q and AQG324, and discrete devices are certified according to AECQ100/101. We can also consider conducting special reliability tests based on customer specific requirements.

Trends and Challenges

When selecting power devices for electric compressors in high-pressure environments, the concept of margin needs to be considered to ensure sufficient safety margin to cope with voltage fluctuations and transient events under various conditions.

Margin is usually based on the following considerations:

1. Steady state voltage margin: In normal working conditions, considering factors such as voltage fluctuations and load changes, the design usually allows the actual working voltage to be lower than the nominal withstand voltage value of the power device. For example, if the highest voltage of the battery system is 400V, the 650V withstand voltage device provides a voltage margin of 250V.

2. Transient voltage margin: In situations such as switch operation or abnormal power grid conditions, there may be instantaneous voltage spikes. At this time, the margin is used to ensure that the device will not be breakdown under these brief but strong voltage surges.

3. Reliability margin: During long-term operation, the withstand voltage performance of power devices may gradually decrease due to factors such as temperature and aging. Therefore, providing sufficient voltage margin can help extend the lifespan of devices and improve the reliability of the entire system.

When a 650V withstand voltage power device is applied to a system with a peak voltage close to its rated value, the designer needs to carefully evaluate whether the voltage margin is sufficient to ensure that the power device can operate safely and stably under all expected operating conditions. With the development of electric vehicle technology, the battery voltage platform continues to rise. Some car companies have a peak voltage of over 500V on their 400V platform. When the existing 650V ASPM modules have insufficient margin in new application scenarios, it will drive the market and technology to develop towards higher voltage withstand levels such as 750V ASPM modules.

On the 800V platform, due to the small size of passenger car compressors, the difficulty of PCB design is relatively high when selecting 1200V modules. Due to the limited internal space of miniaturized compressors, it is necessary to ensure sufficient electrical safety distance between key components when designing high voltage level PCB layouts, which is a challenge for high-density packaged power modules. The module generates greater losses when operating at high voltage, requiring efficient heat dissipation solutions. However, miniaturization design may limit the design of heat dissipation area and path, increasing the complexity of thermal management design. A high voltage level means a higher risk of electromagnetic interference, requiring more detailed PCB wiring design and shielding measures to comply with relevant electromagnetic compatibility standards. It is also necessary to ensure that the insulation performance of the PCB meets the standard at high voltage levels to prevent problems such as creepage and breakdown. The required line width, spacing, and number of layers for high voltage and high current transmission may increase, while also considering reducing the impact of parasitic parameters such as inductance and resistance to optimize switch performance and reduce losses. In response to these challenges and demands, Ansemy is about to launch the next generation of smaller 1200V modules, which integrate the latest FS7 IGBT, to solve the above challenges, achieve more optimized performance, reduce the area by 36%, and also improve the insulation and voltage resistance characteristics, bringing more improvements to the design of electric compressor controllers.

About The Author

This is reported by Top Components, a leading supplier of electronic components in the semiconductor industry. They are committed to providing customers around the world with the most necessary, outdated, licensed, and hard-to-find parts.

Media Relations

Name: John Chen

Email: salesdept@topcomponents.ru